How diamond watches are made

There probably is no place on earth more enamored by bling than the Gulf region. Gold, Swarovski crystals and diamonds – the more sparkly the better! We do have quite the appetite for anything diamond-studded, and there’s no shame in it – it’s a cultural thing. But do you ever wonder how those encrusted items are actually made? Our friends over at Jaeger-LeCoultre have given us a peek into the intricate work of setting gems into their coveted Swiss timepieces.

CRAFTSMANSHIP AT ITS FINEST

Traditional gem-setting is the technique that has ennobled the art of ornamenting an object with the help of precious stones. Contrary to mechanical gem-setting, where the worker merely places the gems in seatings prepared by machining and then draws back the matter over the stones in order to hold them in place, the expert artisans who practice traditional gem-setting personally determine the number of stones and their position, before performing two separate drilling operations: an extremely fine one exclusively intended to define the exact placing of the gem, and a second to enlarge it to the size of each gem.

This slow, painstaking procedure requires literally sculpting the material, repeatedly cutting and re-cutting in order to progressively free the grain of precious metal that will hold the stones. This is followed by a delicate operation requiring great dexterity to precisely adjust the gem in its seating. This skilled manual craftsmanship lends each model an aura of authentic exclusivity even if several of the same kind are produced, since none of them will ever be exactly like another.

The talent of the engravers within JLC is also expressed on certain creations in order to enhance the outlines and further accentuate the beauty of a watch by the combined and expert use of the two techniques. Baguette gem-setting is done using angular-cut gemstones – whether square, rectangular or trapeze-shaped. The gem-setting follows the same steps as outlined above, with the notable exception of the considerably longer manual preparation required before inserting each stone within its chaton or seating.

SNOW SETTING

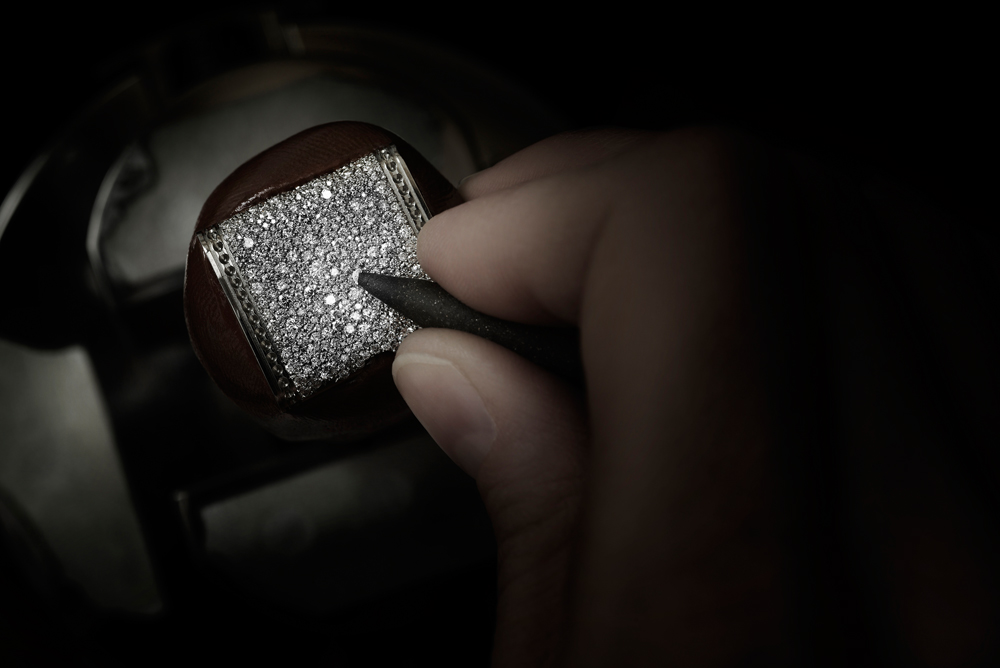

Alongside the time-honoured expertise of hand-crafted gem-setting, Jaeger-LeCoultre has developed a remarkably inventive and unique technique: the snow setting.

For snow setting, the only point of reference of the jewellery artisan is the piece itself or the motif to be set: the motif is created directly on the matter, guided by the twin muses of reflection and creativity. In this delicate art, the slightest slip of the hand can have disastrous

consequences. The diamonds are placed one after the other, side by side, playing with their various diameters to entirely cover the precious metal.

The gem-setter’s work is gradually revealed as the stones, nestling closely against each other, progressively cover the entire metal

surface. This inventive freedom requires extreme skill and meticulous care. In addition to the complexity of the task and the time required to accomplish it, the selection of diamonds itself calls for considerable expertise, since the tiniest diameters must be able to merge seamlessly into the most daring designs.